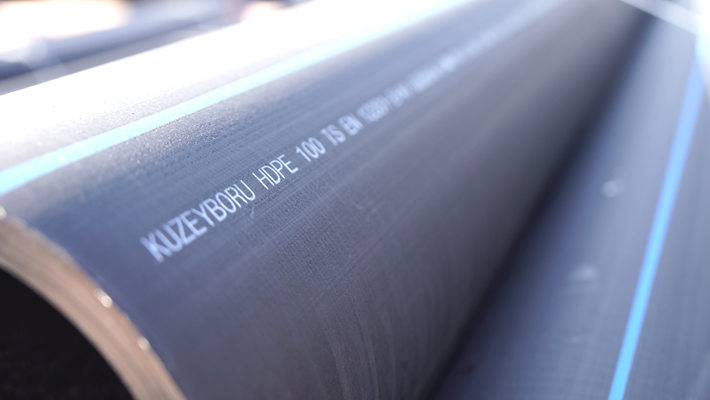

HDPE PIPE and FITTINGS

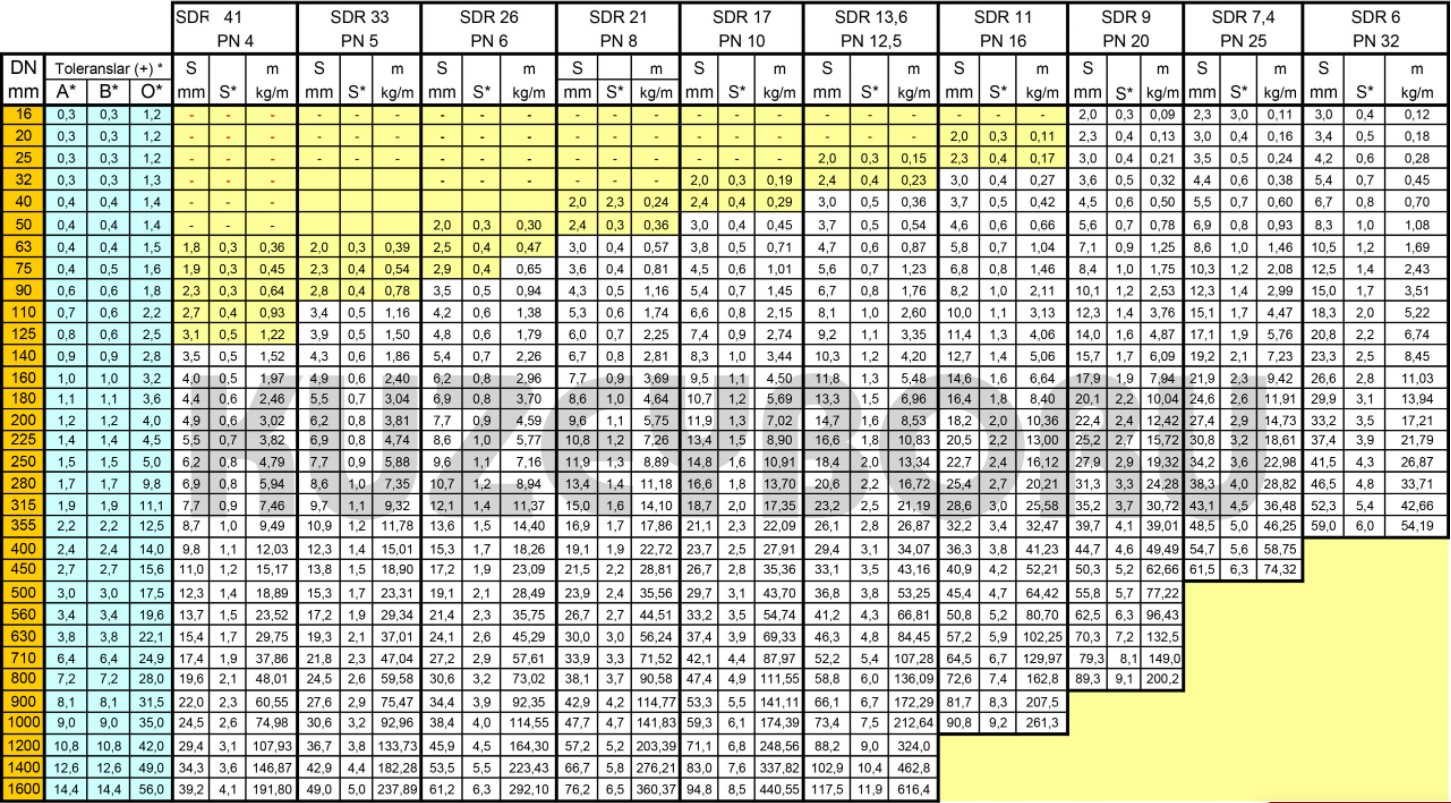

Hdpe Pipe in desired diameters between 20 mm – 1600 mm and in Pn4-Pn32 pressure classes are indispensable for your projects with their high performance and quality.

Hdpe Pipes Production; It is the most used plastic raw material today. It is known that it appeared for the first time in history in 1898. Crude oil is used in the production of polyethylene raw material. Therefore, the production and availability of polyethylene raw material is directly proportional to crude oil.

Hdpe pipe and fittings have many advantages, their high quality, durability of pipes and fittings, light weight, ease of loading and transportation, fast and easy assembly have made them the best choice for your projects.6