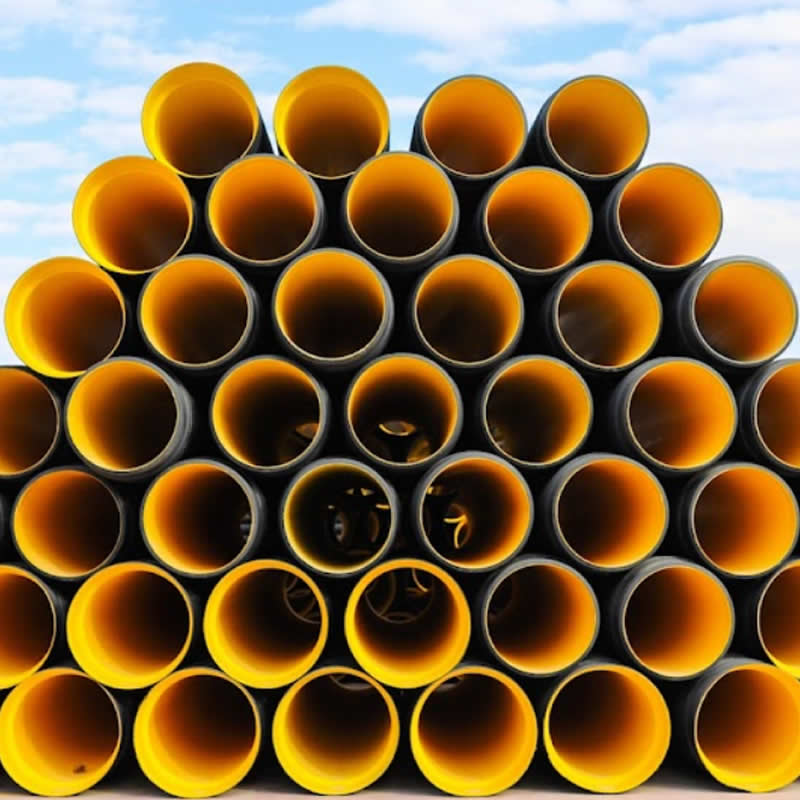

Corrugated pipes are a type of flexible tubing with a ribbed exterior, also known as corrugations. They are commonly used in various applications due to their durability, flexibility, and resistance to harsh environmental conditions. Corrugated pipes come in different materials and sizes, making them suitable for various applications.

Here are some of the application areas of corrugated pipes:

- Drainage Systems

One of the most common applications of corrugated pipes is in drainage systems. They are used to move rainwater, stormwater, and other types of runoff from residential, commercial, and industrial areas to a collection point or disposal site. Corrugated pipes are flexible, allowing them to be easily installed around obstacles and curves. They are also available in different sizes and materials, making them suitable for different soil types and water pressures.

- Culverts and Bridges

Corrugated pipes are commonly used as culverts or small bridges in transportation infrastructure. They are used to move water under roads, railroads, or other structures, reducing the risk of flooding or damage. Corrugated pipes used in these applications are typically made from durable materials such as high-density polyethylene (HDPE), which can withstand heavy loads and harsh environmental conditions.

- Sewer Systems

Corrugated pipes are also used in sewer systems to transport wastewater from households and businesses to treatment plants. They are commonly used in areas where the soil has poor permeability, making it difficult to install traditional sewer systems. Corrugated pipes used in sewer systems are typically made from materials that are resistant to chemicals and abrasion, such as PVC or polypropylene (PP).

- Agriculture

Corrugated pipes are commonly used in agriculture for irrigation systems, drainage systems, and water conveyance. They are often used to transport water from a water source to fields or crops. Corrugated pipes used in agriculture are typically made from materials that are resistant to UV radiation and chemicals, such as HDPE.

- Mining

Corrugated pipes are also used in mining for ventilation, drainage, and other applications. They are often used to transport water, chemicals, and slurry to processing plants or disposal sites. Corrugated pipes used in mining are typically made from materials that are resistant to abrasion, chemicals, and high temperatures, such as HDPE or polyvinyl chloride (PVC).

Corrugated pipes have many applications due to their flexibility, durability, and resistance to harsh environmental conditions. They are commonly used in drainage systems, culverts and bridges, sewer systems, agriculture, and mining. Corrugated pipes come in different sizes and materials, making them suitable for various soil types, water pressures, and chemical environments.